Visits: 1152

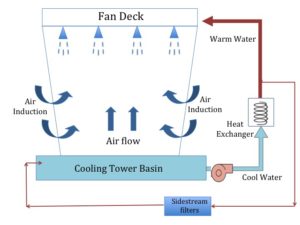

Sidestream filtration continuously filters a percentage of the cooling water to remove debris and particles from the circulation. And return filtered water to the cooling tower basin. It is a cost-effective alternative to full flow filtration that can easily improve the water quality to reduce water consumption and ensure the efficiency of the cooling systems.

These systems remove suspended solids, organics, and silt particles from a portion of the water system on a continuous basis, reducing the likelihood of fouling and biological growth. Sidestream filtration helps to control other issues in the system such as scaling and corrosion. Thus improving system efficiency and often reduces the amount of water used for blowdown.

Conventional sidestream filtration systems are generally sized to filter up to 20% of the overall system flow. Filters are selected based on the percentage of flow that the sidestream filtration system is designed to handle. For example, in a cooling system with a recirculation rate of 1500GPM, a filtration system sized to handle 10% of the recirculation would be sized to handle 150GPM.

KEPD systems require only about 5% - 10% of the system water to achieve optimum water conditions. This application has been widely used and endorsed by steel mills, petrol chemical, and power plants.

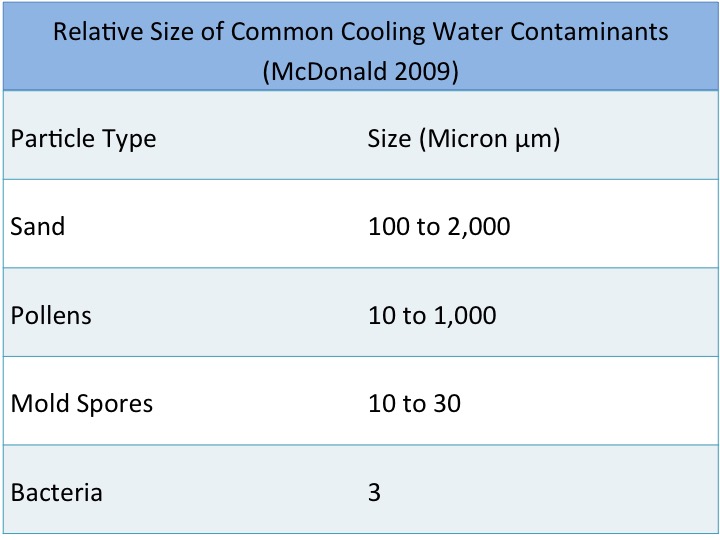

Particle Size

Filters are rated by the size of the particles that can be removed, measured in microns. Suspended solids in cooling towers typically range in sizes from 1 to 50 microns as in the table below. In general, 90% of the particles in cooling towers are smaller than 10 microns (Bobby et al. 2001).

Benefits of Sidestream Filtration

Sidestream filtration increases water and energy efficiency and reduces cost,

-

Reduction in water consumption - Demand for make up water in cooling towers decrease as the cycle of concentration (COC) increases. Higher COC means lesser blowdowns which translates to water savings.

- Reduction in energy consumption - Sidestream filtration reduces deposition potential on the surfaces of heat exchangers. Organic or inorganic fouling on heat exchangers increases energy demand.

- Reduction in chemical consumption - Chemicals are used to bind suspended solids and inhibit deposit formation. Effective sidestream filtration significantly reduce suspended solids in the system. Cleaner water reduces the reliance on water treatment chemicals.

- Lower maintenance cost - Sidestream filtration continuously remove suspended solids from the circulation. This process prolongs system operation between sump cleaning schedules.

Traditionally, cooling tower sump cleaning is a major cost centre in maintenance. Costs associated with the cleaning process include labour, water loss and cleaning chemicals. - Improving production - Auxiliary equipments operates at higher temperatures when heat is not transferred effectively. A well maintained cooling tower reduces production stoppages, unscheduled repair and maintenance of equipment.